I. CORE CONFIGURATION, PRECISE NAVIGATION

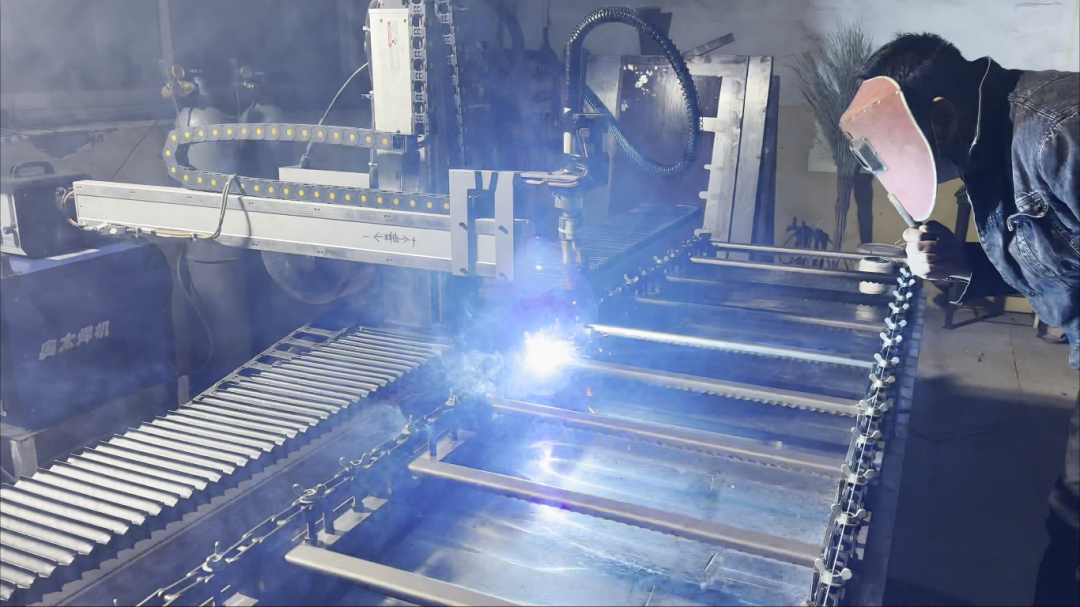

Chnchi's ZE Series servo motors are the powerful partners of six-axis welding robots. Equipped with a 23-bit photoelectric encoder, it’s like giving the robot "eagle eyes"—able to accurately capture every subtle movement command. Whether positioning the welding start point or tracking complex weld seams, it handles them effortlessly, steadily improving welding accuracy.

With a diverse range of power options, the 400W and 1kW models meet the needs of various welding tasks. The 1kW model comes in both brake and non-brake versions. The brake version offers reliable emergency stopping power, preventing any slippage in special working conditions, while the non-brake version provides excellent cost-effectiveness, allowing companies to choose flexibly based on their needs. Paired with the MZ860N series EtherCAT bus-type servo drive, the collaborative performance is outstanding.

II. BUS POWER, COMMANDING PERFORMANCE

The EtherCAT bus-based servo drive significantly enhances the stability and coordination of six-axis welding robots.

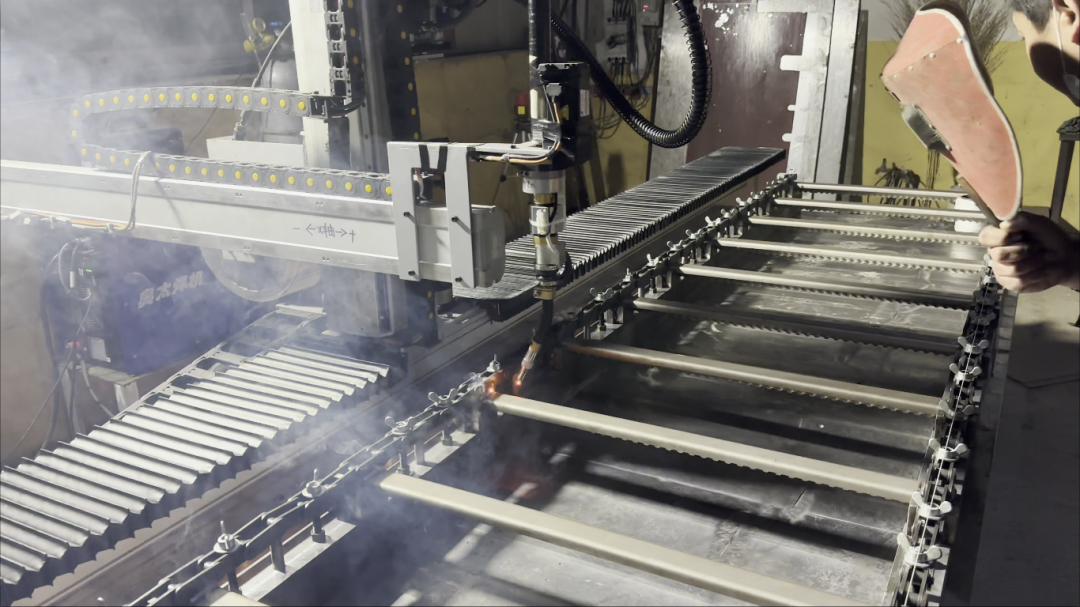

In terms of stability, leveraging an advanced communication protocol, it ensures high-speed and reliable data transmission, effectively rejecting signal interference and packet loss. Even during prolonged welding operations, the motor remains jitter-free and movements stay precise, resulting in uniform and aesthetically pleasing welds while drastically reducing defect rates. It’s like building a "highway" for the robot—where commands travel smoothly and efficiently.

As for coordination, the six axes of the robot work like a group of highly synchronized dancers. Zhongzhi’s bus servo system enables real-time data synchronization among joint motors and ensures rapid response to commands. Whether switching between complex welding postures or making rapid multi-axis adjustments, the motion remains fluid and precise, leading to a substantial increase in welding efficiency.

III. TECH-DRIVEN, WORRY-FREE WELDING

CHNCHI Servo stands out in welding applications with its exceptional technological strengths.

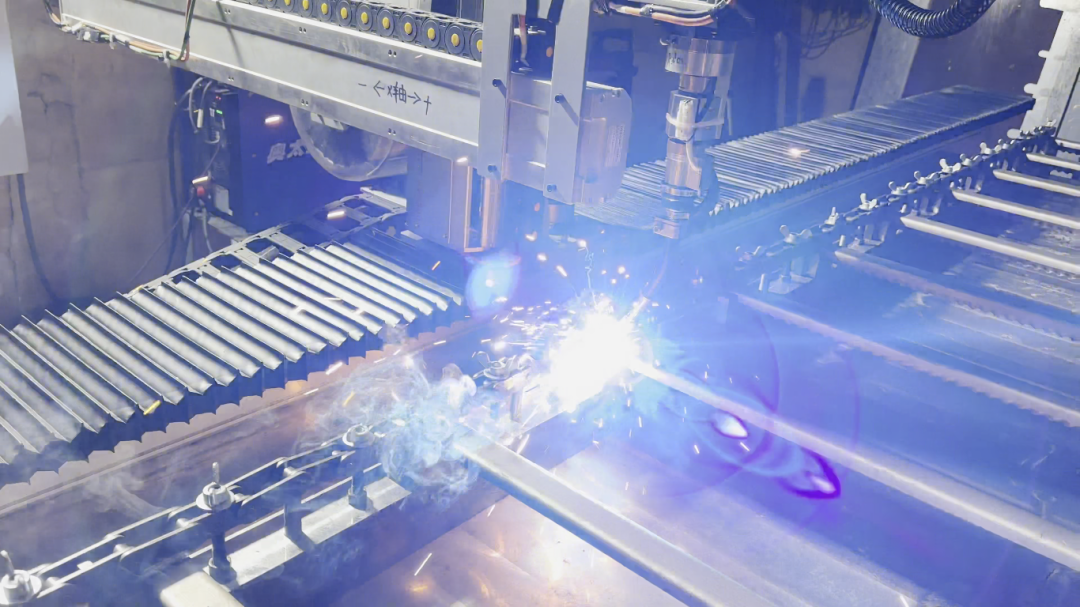

Enhanced Welding Speed: The servo system ensures precise control, enabling rapid yet smooth acceleration and deceleration of the welding torch. This reduces idle motion, optimizes path planning, shortens cycle times, and significantly increases workpiece output.

Superior Weld Quality: Built on high-precision positioning, the servo motor’s refined torque control provides an added layer of excellence. It delivers gentle handling for thin plates and robust power for thick materials, ensuring consistent penetration depth and weld quality that meets the demands of real-world production.

CONCLUSION

Amid the wave of Industry 4.0, CHNCHI Electric Nanjing Co., Ltd. remains steadfast in its original aspiration, dedicating itself to the research, development, and innovation of servo motors and drives. We deeply understand that only by consistently delivering high-quality, high-performance products can we empower the manufacturing industry to navigate fierce market competition and sail ahead with confidence. In the future, Zhongzhi Electric will continue to strive forward, constantly exploring technological boundaries to tailor power solutions for diverse industrial scenarios, working hand in hand with partners to create a brilliant future.

Product Center

Productcontact us

contactTel:025-58822988

Phone:18913354648

Url:http://www.zzservo.com

Add:95th Xingangwan Road,Luhe Development Zone, Luhe District, Nanjing City, Jiangsu Province, China