In the labeling machine industry, technological innovation is a crucial driver of productivity growth. The servo motors and drives developed by CHNCHI Electric (Nanjing) Co., Ltd. have become the preferred choice for many labeling equipment manufacturers to enhance product performance, thanks to their reliable and efficient operation.

01 Customer Needs: Balancing Efficiency and Precision

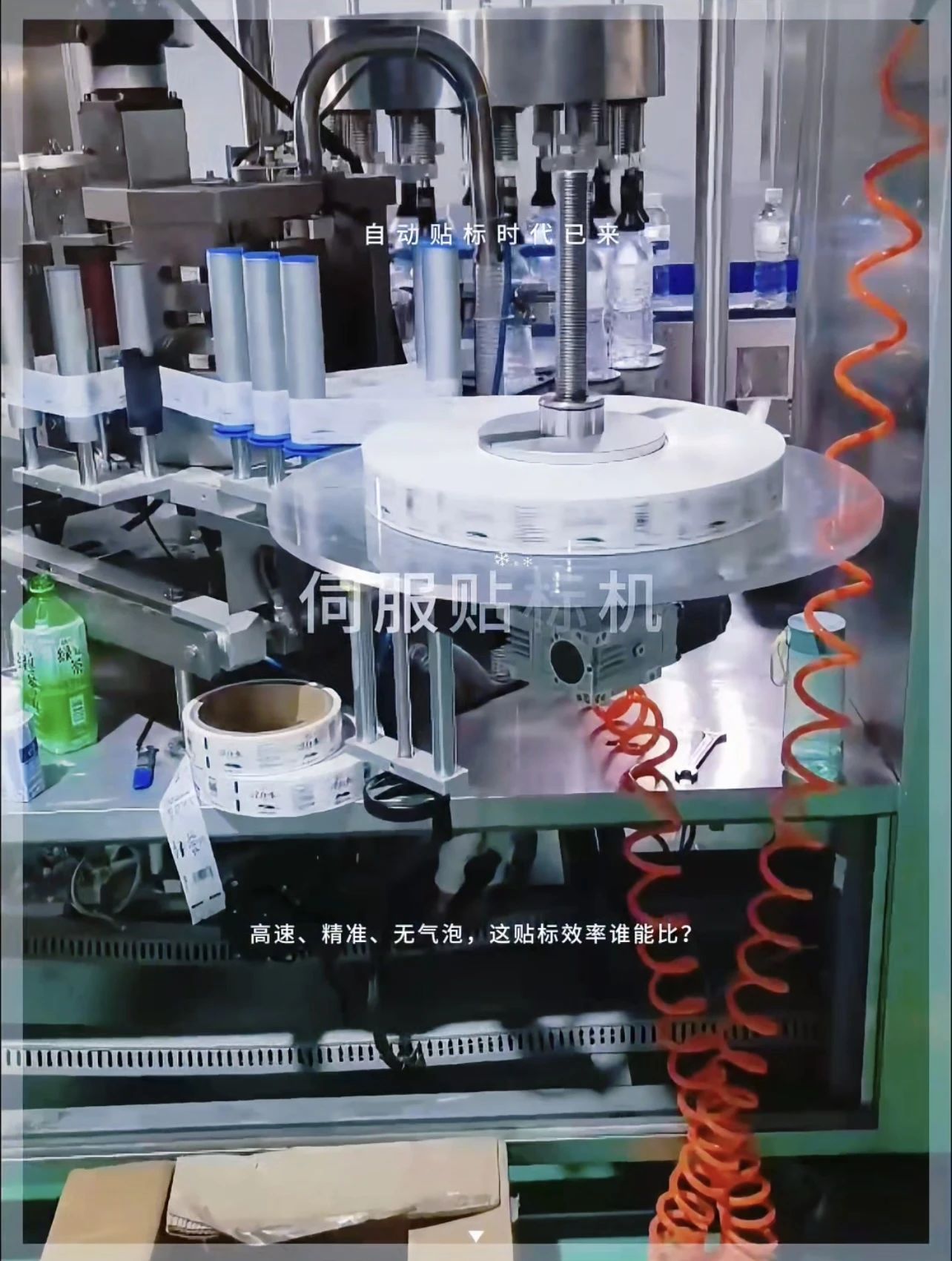

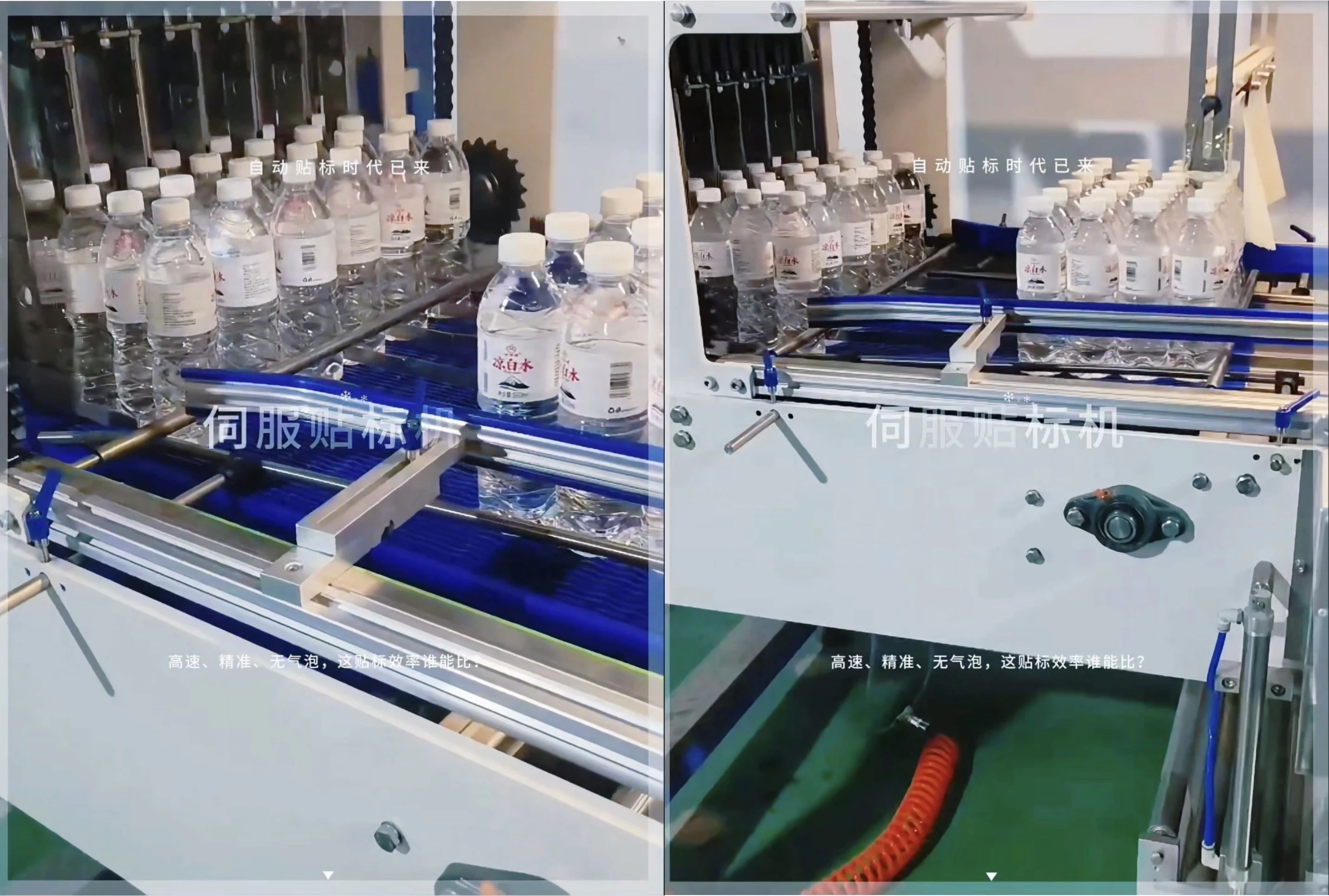

A well-known labeling machine manufacturer is facing increasing market competition and growing customer demand for higher performance equipment. In terms of efficiency, clients expect each labeling machine to achieve a continuous labeling rate of 500 bottles per minute. Regarding precision, the machines must ensure accurate labeling on containers of various shapes — including flat, curved, cylindrical, and irregular surfaces — while strictly controlling positioning deviation. Additionally, the equipment needs to be easily integrated with upstream and downstream machinery to enable fully automated production processes.

02 The CHNCHI Solution: Customized Servo Systems

In response to the customer's needs, Chnchi Electric swiftly delivered a tailored solution comprising the MZ800 series pulse-type servo drives and ZE series 400W servo motors. Equipped with a 17-bit magnetic encoder, the motor enables high-precision turntable control and high-speed positioning. The drive and motor are optimally matched, ensuring accurate execution of diverse control commands.

Chnchi’s servo system offers extensive functionality, capable of meeting labeling requirements for containers of various shapes. It integrates seamlessly with upstream bottle arranging equipment and downstream packaging lines, enabling end-to-end automation. The modular design further simplifies installation, debugging, and maintenance of the labeling system.

03 Outcome: Stable and Reliable Performance

In practical application, this servo system has demonstrated stable and reliable performance. It achieves a labeling speed of 600 bottles per minute, meeting the customer's efficiency requirements. During labeling on containers of various shapes, it effectively controls positioning deviation, ensuring consistent labeling quality. The improvement in production efficiency has contributed to reduced labor costs and lower defect rates. Furthermore, the system’s reliable operation has minimized equipment downtime and decreased maintenance expenses. The customer has highly endorsed Chnchi Electric’s servo solution and plans to adopt it across more models of their labeling machines.

Conclusion

CHNCHI Electric (Nanjing) Co., Ltd. has demonstrated the value of its servo systems in the labeling industry through professional expertise and reliable products, backed by real-world cases. If you have requirements in the field of labeling machinery, we welcome you to choose Chnchi Electric. Let’s work together to explore efficient and precise labeling solutions.

Product Center

Productcontact us

contactTel:025-58822988

Phone:18913354648

Url:

Add:江苏省南京市六合区龙池街道新港湾路95号